Salt spray testing is an environmental test primarily used to assess the corrosion resistance of pro...

As a leader in the testing and certification industry, Tonggui Testing holds a leading position in the market with its profound technical expertise and rich industry experience. The company has established a professional and excellent technical team, whose members not only possess solid professional knowledge and can accurately grasp various testing standards, but also have rich practical experience to cope with complex and diverse testing needs and tailor solutions for customers. To ensure the scientificity and accuracy of testing, Tonggui Testing actively introduces international cutting-edge testing equipment, creates high standard testing laboratories, strictly controls every testing process, and ensures the authenticity and reliability of testing data. At the same time, the company adheres to the customer-oriented service philosophy and has launched a one-stop service system, providing customers with comprehensive and thoughtful services from project consultation to report delivery, saving customers time and energy and winning widespread praise from customers.

Testing standards

Salt spray testing simulates a salt spray environment to test the corrosion resistance of product surface coatings, metal materials, etc. There are various common standards. Internationally, ISO 9227 has formulated relevant specifications for salt spray test of artificial atmosphere corrosion test, which specifies key parameters such as salt solution concentration, pH value, spray mode, etc., and is applicable to salt spray corrosion test of various metal and non-metallic coatings. The ASTM B117 standard developed by the American Society for Testing and Materials is a classic standard in the field of salt spray testing, widely used in industries such as automotive and aerospace, with clear requirements for testing equipment, operating procedures, and result evaluation. In China, GB/T 10125 "Corrosion Test in Artificial Atmosphere - Salt Spray Test" is equivalent to ISO 9227 standard. Combining with the actual situation in China, detailed specifications have been made for each link of salt spray testing to ensure the standardization and consistency of the testing. According to different testing purposes and product characteristics, salt spray testing is divided into neutral salt spray test (NSS), acetic acid salt spray test (AASS), and copper accelerated acetic acid salt spray test (CASS) to simulate different corrosion environments.

Applicable products

Automotive components: The body, chassis, wheels, and other parts of a car are exposed to outdoor environments for a long time and are susceptible to salt spray erosion. Through salt spray testing, car manufacturers can evaluate the corrosion resistance of components, optimize product design and surface treatment processes, extend the service life of cars, and improve the reliability of vehicles in harsh environments such as coastal areas and winter salt roads.

Aerospace equipment: Aircraft will travel through different climate zones during flight, and some components will come into contact with salt spray in oceanic climates. The key components of aerospace equipment, such as engine blades, landing gear, etc., require strict salt spray testing to ensure their safety and reliability in complex environments and ensure flight safety.

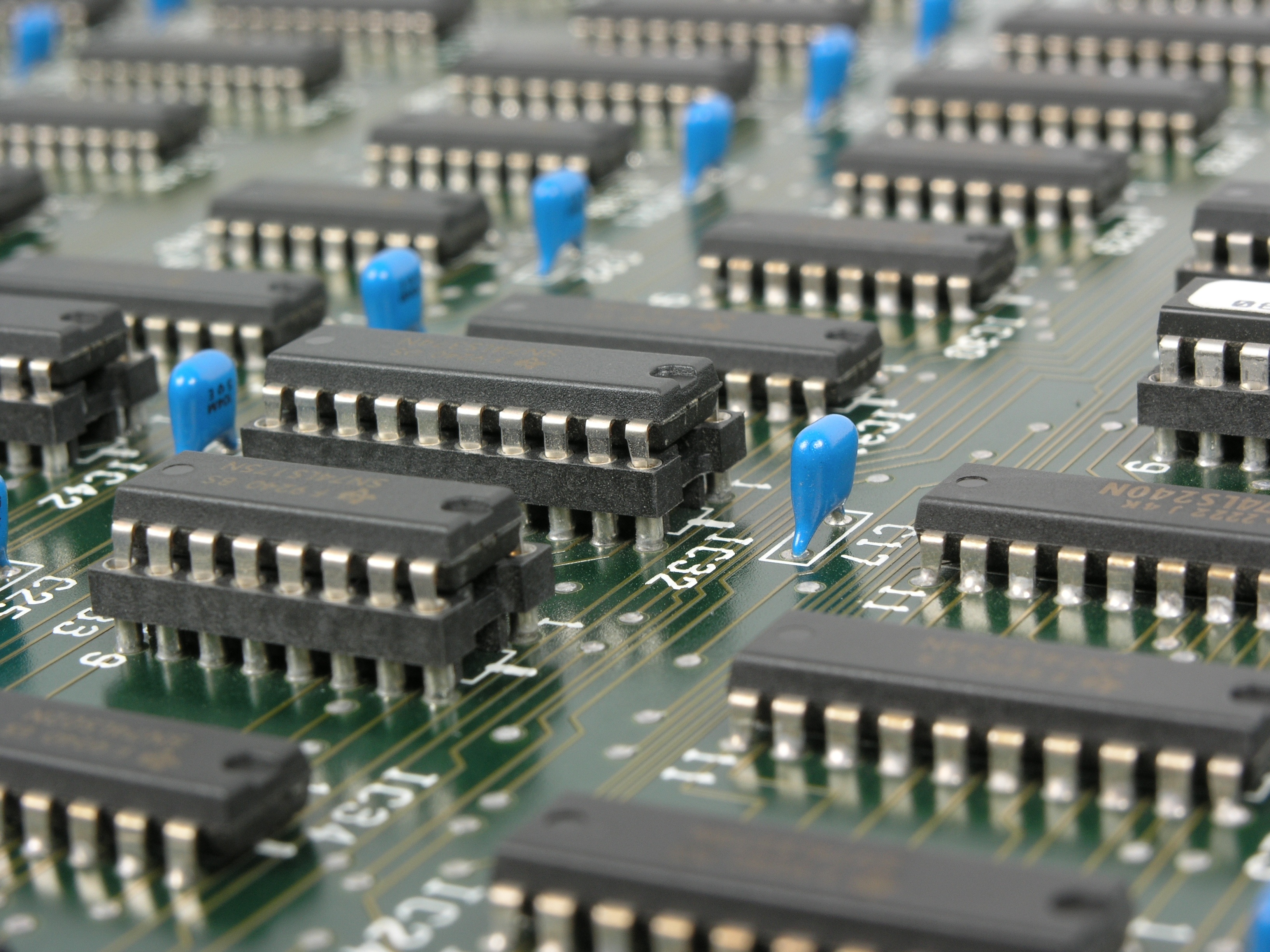

Electronic devices: The casing and internal circuits of electronic devices such as smartphones and tablets are prone to corrosion in humid salt spray environments, leading to device malfunctions. Salt spray testing helps electronic device manufacturers verify the protective performance of their products, adopt appropriate protective measures, avoid economic losses caused by salt spray corrosion, and improve product quality.

Building materials: Building hardware, door and window frames, curtain walls, and other building materials that are exposed to natural environments for a long time may rust and be damaged by salt spray, affecting the aesthetics and safety of the building. Salt spray testing can help building material suppliers and construction companies choose materials with good corrosion resistance, ensuring the stability and durability of building structures.

The salt spray testing service provided by Tonggui Testing fully leverages the company's advantages: a professional technical team develops personalized testing plans based on customer product characteristics and testing requirements; During the testing process, we strictly follow international and domestic standards, use advanced testing equipment to monitor the testing process in real time, and ensure the accuracy and repeatability of the test data; After the testing is completed, provide customers with detailed testing reports and provide targeted improvement suggestions based on professional analysis to help customers enhance the corrosion resistance of their products.

Why choose general testing

Professional team guarantee: The professional team of Tonggui Testing has a deep understanding of salt spray testing standards and techniques, and can provide customers with comprehensive technical support during the testing process, solve various technical problems, and ensure smooth testing.

Advanced equipment assistance: The company has introduced international cutting-edge testing equipment that can accurately simulate various complex salt spray environments, meet the testing needs of different products, improve testing efficiency, shorten testing cycles, and help customers quickly obtain testing results.

One stop service is worry free: The one-stop service model for general testing allows customers to enjoy a convenient and efficient service experience from consultation to report delivery without worrying about tedious testing processes.

Good reputation witness: Over the years, Tonggui Testing has established a good reputation in the industry with professional services and high-quality testing results, and is a reliable partner for customers to conduct salt spray testing.